EGGER

Turo® Vortex Pumps

Turo® Vortex Pumps with a completely open spherical channel. Only 15% of the pumped fluid comes into contact with the impeller. Around the world, thousands of pumps have proven themselves with decades of excellent service.

Freedom from clogging by solids

High, sustained efficiency

Large, open spherical channel

Reduced wear

Low life cycle costs

Long service life

Economic storage, thanks to its modular design

Municipal and industrial wastewater

Every kind of sludge

High concentrations of fibrous suspensions

Chemical and crystalline suspensions

All viscous materials

Numerous abrasive and corrosive fluids

Dimension : DN 32-200mm

Flow rate : up to 200 l / s

Head :up to 140 m, 460 ft

Pressure :up to 30 bar / 440 psi

Temperature :up to 180°C

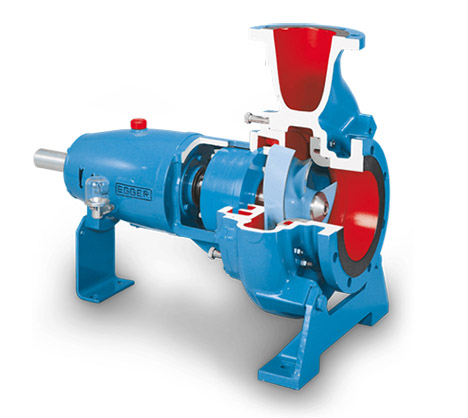

Process Pumps EO/EOS

The high-performance pump for homogeneous liquids containing high concentrations of solids and high gas contents. Different numbers of impeller blades for large and small particle sizes.

High suction capability

High efficiency

Externally adjustable wear plate for constant sustained output

Multifaceted applicability

Low life cycle costs

Long service life

Economic storage, thanks to the Egger modular system

Demanding fluids in the chemical and petrochemical industries

Multiphase mixtures for reactor loops

Aerated fibre suspensions in the pulp and paper industry

Wastewater and viscous materials in wastewater technology

Numerous abrasive and corrosive fluids

Dimension:DN 50-500 mm

Flow rate:1500 L/S

Head:up to 150 m

Pressure:up to 30 bar / 440 psi

Temperature:up to 180°C

Elbow Pumps RPP/RPG

The typical pump for large capacity at low discharge heads (circulation pump with axial impeller). Available in welded or cast construction with reinforcing ribs.

Robust construction – long service life

Gentle transport

Fiber repellent

Saving energy – suction behavior

Tough applications with corrosive fluids

Crystallisation plants

Vaporisation plants

Reactor loops

Sludge recirculation

Pumping stations

Dimension:

DN 250-700 mm 10-28”(cast)

DN 250-1400 mm 10-56”(welded)

Flow rate::up to 8300 l / s

Head:up to 10 m, 33 ft

Pressure:up to 6 bar, 90 psi

Temperature:up to 140°C

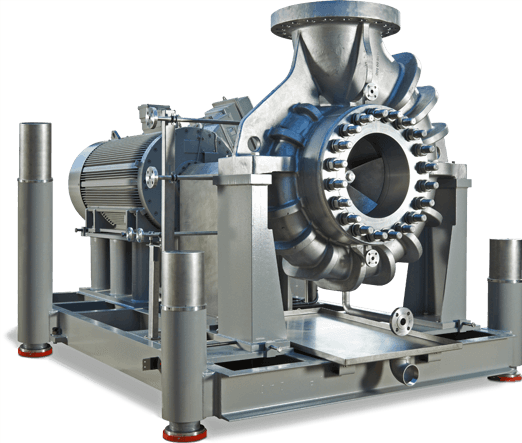

Reactor Pumps HT/HPT

The performant reactor pump developed for high temperature and high pressure applications in the chemical and petrochemical industries. Since many years a reference to handle multiphase liquids such as chemical mixtures with high gas content. Egger HT/HPT pumps are specially designed for loop reactor continuous circulations with catalyst and high gas contents.

Pumping of fluids with gas contents up to 25 % vol.

Centerline mounted process design according to API 610 OH2

Multiphase liquids for loop reactor circulation

Boiling liquids with low available suction head

Abrasive and corrosive liquids

Chemicals with high system pressure and high temperature

Complex media in the chemical and petrochemical industries

Dimension:DN 50 – 500 mm (2 – 20“)

Flow rate:up to 1500 l / s,

Head:up to 150 m, 492 ft

Pressure:HT up to 45 bar, 650 psi

HPT up to 100 bar, 1450 psi

Temperature:up to 330°C / 625°F

Material:Austenitic, Duplex, Super Duplex, High Nickel alloys,…

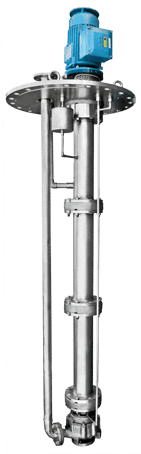

Submerged Pumps SG/SGD

Egger submerged sump pumps can be used in all explosion endangered zones. Since 2000, Egger owns a valid Type Examination certificate and can rely on many years of experience in the use of submerged sump pumps in Zone 0 explosion-risk environments.

No bearings in the pumped liquid

Suited for fluids containing solid particles

Submerged lengths of up to 10 meters possible

Tight pit cover to the atmosphere available

Drainage of tank pits

Safety tanks

Storage tanks

API separators