SAMMI

Sammi Line Blind provides many kinds of blind valve for safety in operation and maintenance, in the meanwhile to save money and reduce manpower.

Compare with Typical Process:

Typical Process

Sammi Process

| Size Ranged | Typical | Sammi Line Blind |

1/2”〜14 ” (DN15〜DN350) |  |  |

16”〜48 “ (DN400〜DN1200) |  |  |

- Saving cost for maintenance

- No consumable parts except gaskets

- No tools, wedges, crane, bolts are necessary

- Quick and Positive action in emergency

- Prevent vacuum losing

- Prevent contamination by mixing

- Prevent leaking accident in service

- Prevent environmental pollution

Applications:

Petrochemical Plant

Oil Refinery Plant

Iron & Steel Mill

Thermal & Nuclear Power Plant

Cement & Pulp Industries

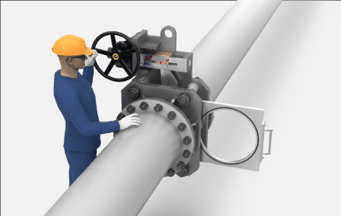

It takes within 3 minutes for one operator to blank a line, operating the handwheel and rotating the blind into place without line spreading. All inline movement is internal, eliminating the potential for pipe-joint stress. As one of the most popular model, quick operation with no line spread and correct spectacle positioner shall make easy and safe pipe line isolation.

One operator turns handwheel and unique gear-set mechanism makes a gap without pipe spreading. All blinding process completes within 3 minutes. Sturdy and simple design shall make high reliability with the most advanced technology and durability.

This type has good advantages in oil terminal & offshore applications where is limited installation space and marine pollution is strictly prohibited. The special design prevents ground pollution and it allows to install at parallel pipe lines.

This type is designed for replacement of existing valves, limited F-F dimension or large diameter pipeline applications or limited space for installation. It is designed for easy installation between flanges. The compact design also reduces weight and requirement for extra pipe support.

Goggle type of Line Blind is positive solution for large diameter, high temperature and toxic gas condition for maintenance and inspection.

The traditional style of line blind offers a broad range of pressures and a lower cost. Pipe line needs to be spread for operation.

Automated Line Blind Valves are used for remote control operation, frequent cycle, or critical fluid application Sammi provides automated system by AOV, MOV or oil hydraulic source.