SCHURCO

Schurco Slurry® has engineered products and services to deliver the highest performance at the best value for our customers in mining, dredging, quarrying, and industrial processing around the world.

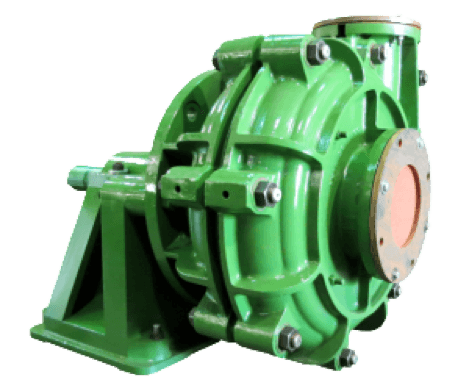

S-Series(Warman®AH®)

With a wide variety of impeller designs, material selections, and shaft sealing options, the Schurco S Series pump can pump high solids at high heads in corrosive duties. Its simple and easy to maintain construction offers the best life-cycle cost on the market today.

Discharge range:

1” to 18” [25mm to 450mm]

Heads : 240 ft [73 m

Flows rate:22,000 gpm [5,000 m3/hr]

Bottom ash / fly ash transportation

Fume desulfurization plant

Pulp / Paper Mill

Industrial processing

Pulp and paper industry

Wet crusher related applications

Chemical pulp delivery

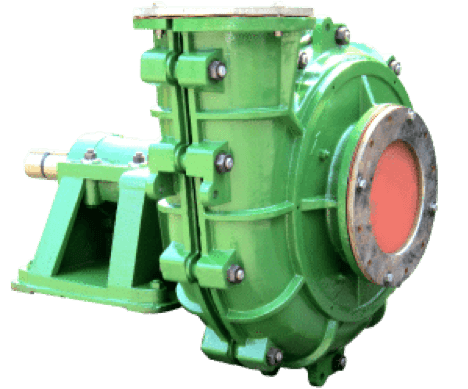

L-Series(Warman® L® & M®)

Higher efficiency, volume focused impellers deliver world class performance for Slurry Classes III and below. Reaching heads of nearly 200 ft, this pump delivers solid pumping performance for a wide variety of applications.

Discharge range:

4” to 22” [100 mm to 550 mm]

Heads to:180 ft [55 m]

Flows to:30,000 gpm [6,800 m3/hr]

Bottom ash / fly ash transportation

Fume desulfurization plant

Pulp / Paper Mill

Industrial processing

Pulp and paper industry

Wet crusher related applications

Chemical pulp delivery

V-Series

A true cantilever pump available in alloy and elastomer wet-end material options that operates well in a variety of sump conditions or on floating dewatering platforms. The pump features no submerged bearings or seals thus eliminating the primary mode of failure in centrifugal slurry pumping.

Discharge range:

1-1/2” to 10” [40 mm to 250 mm]

Heads to:160 ft [50 m]

Flows to:6,000 gpm [1,350 m3/hr]

Chemical processing

Sewage treatment

Factory pumping

Iron and steel scrap water transportation

Spare Parts for Schurco Slurry® and Warman® Pumps

Schurco Slurry® manufactures quality metal and elastomer replacement parts fully compatible with Warman® pumps, and provides value to customers through fair pricing and lead times that are some of the lowest in the market. We stock millions of dollars of pumps and parts globally, all of which are interchangeable with Warman® slurry pump parts. We maintain a global distribution network that stands ready to serve your process needs.

All parts compatible with the Warman® slurry pumps have been rigorously reverse engineered using FaroArm® technology with 2-D and 3-D modeling. First article inspection involves comparison to OEM parts followed by fit testing. All impellers have been performance tested to certify them against OEM performance. Schurco Slurry manufactures replacement parts for other manufacturers as we do our own: with technical expertise, quality, fair pricing, and product availability for the end-user.

Hi-Chrome Alloy Wet End Components

Elastomeric Wet End Components