VACUUM SYSTEM

NASH Liquid Ring Pump | Garo Liquid Ring Pump | Hoffman Blower | Lamson Blower

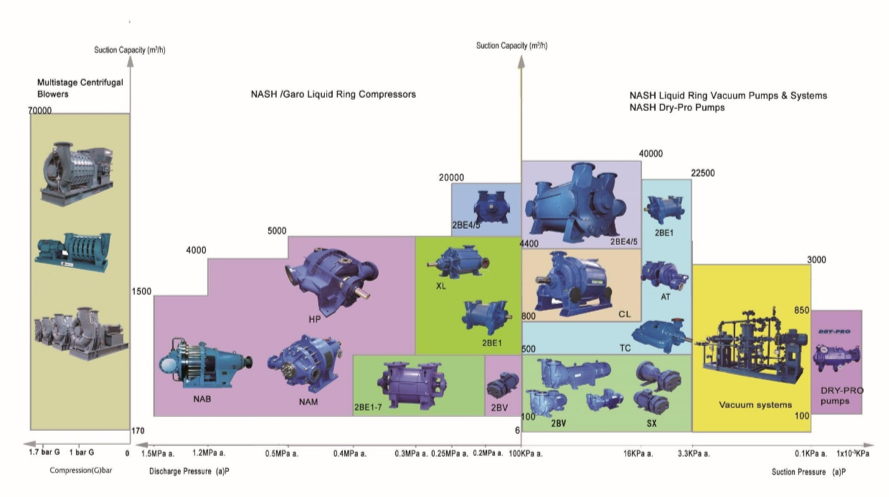

Gardner Denver Nash provides a full range of liquid ring vacuum / compressors and dry vacuum pumps…etc.

Liquid Ring Vacuum Pumps:

Nash is committed to the highest standards in production and safety. We have many ISO certificates, issued to our facilities worldwide and continue to improve our quality by optimizing internal processes.

NASH liquid ring vacuum pumps are certified to ATEX and other global industrial standards.

- Accepts carryover – soft solids, moisture, slugs, chemicals, and more will not harm the pump but are washed out through the pump discharge

- Cool & quiet operation – the pump runs cool owing to the circulation of the sealing water inside the pump. The operation is a quiet and low vibration

- Continuous operation for any process – the pump can operate constantly and continuously at any vacuum level up to 1” HgA

- Easy maintenance and longer pump life – our pump has one moving part. Therefore, wear is less, making maintenance simpler and more affordable

- Environmentally safe – our pumps do not require oil changes, filters, oil-pans, condensers, etc. so operating facilities run clean, free of oil contamination and oil discharge to sewers

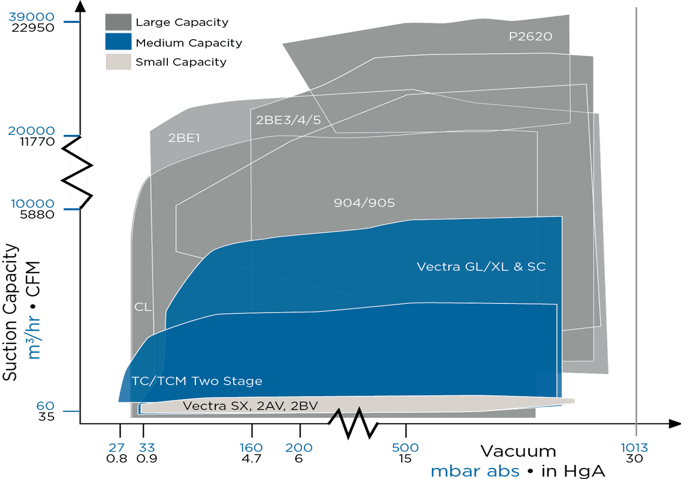

- Small Capacity Liquid Ring Vacuum Pumps: (Vacuum levels up to 29″ HgA, 1.5 HP to 10 HP)

- Medium Capacity Liquid Ring Vacuum Pumps:(Vacuum levels up to 28″ HgA, 10 HP to 200 HP)

- Large Capacity Liquid Ring Vacuum Pumps :(Vacuum levels up to 25″ HgA, above 200 HP)

- We also provide non-seal Liquid Ring Vacuum pump for solving VOC and Toxic issue.

Dry Vacuum Pumps

Reliable performance and low lifecycle costs

- Capacity up to 1,500 ACFM (up to 2,500 m3/h),Vacuum Range: to 0.02 Torr (to 0.03 mbar)

- DRY-PRO pumps can handle corrosives, organics, inorganics, and solvents because of its oil-free, non-contacting screw design making it an ideal choice for chemical, plastics, industrial, petrochemical, and packaging industries.

- We offer quick shipment with plug & play installation for a variety of dry vacuum processes in the

pharmaceutical and fine chemical industries

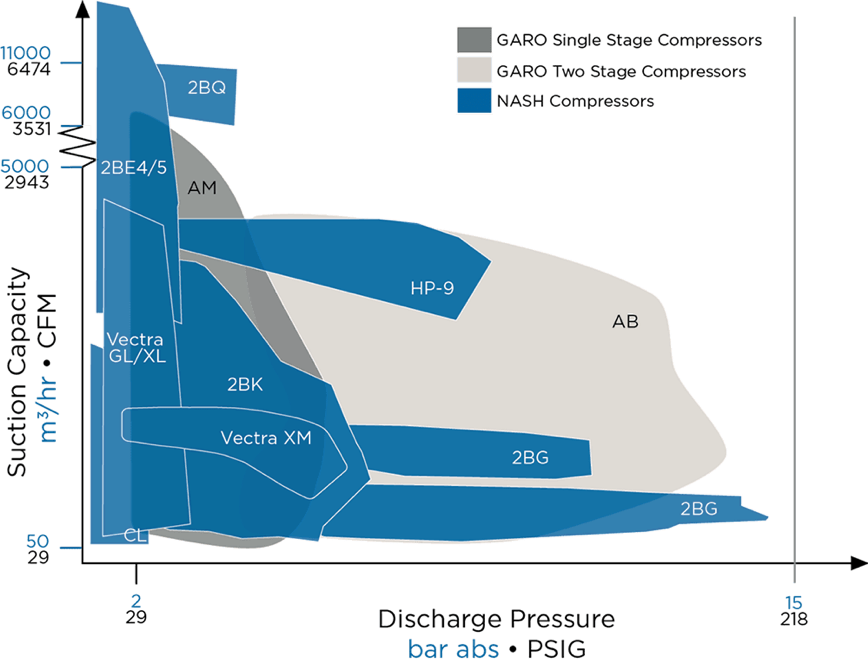

NASH Liquid Ring Compressor

NASH liquid ring compressors require minimal care and low maintenance. These compressors reduce power and operating costs by handling higher capacities with less energy.

- Ability to handle carryover resulting in minimal process problems and an increase in uptime; intended for severe applications

- The long design life of 40+ years that offers the highest reliability

- No internal lubrication required, which means less maintenance and less downtime

- No metal-to-metal contact and constant wear-free performance

- Cool running, minimal temperature rise between inlet and discharge that is ideal for explosive gases and vapor recovery applications

- Only one moving part for simple and reliable operation

Capacity Range:

- Low Pressure Liquid Ring Compressors (Up to 30 PSIG or 2 bar abs.)

- Medium Pressure Liquid Ring Compressors (Up to 75 PSIG or 6 bar abs.)

- High Pressure Liquid Ring Compressors (Over 75 PSIG or 6 bar abs.)

Applications of Liquid Ring Compressors:

NASH liquid ring compressors are the preferred solution and designed for harsh and demanding processes or any other type of wet, corrosive, dirty, or explosive gas including:

- Flare gas recovery

- Flare gas compression

- Vinyl chloride monomer recovery (VCM)

- Vent gas recovery

- Vapor recovery

- Hydrogen compression

- Oxygen/ozone compression

- Wastewater treatment methane compression

- Carbon dioxide compression

- Waste gas compression, power plants

Multi-Stage Centrifuge Blower

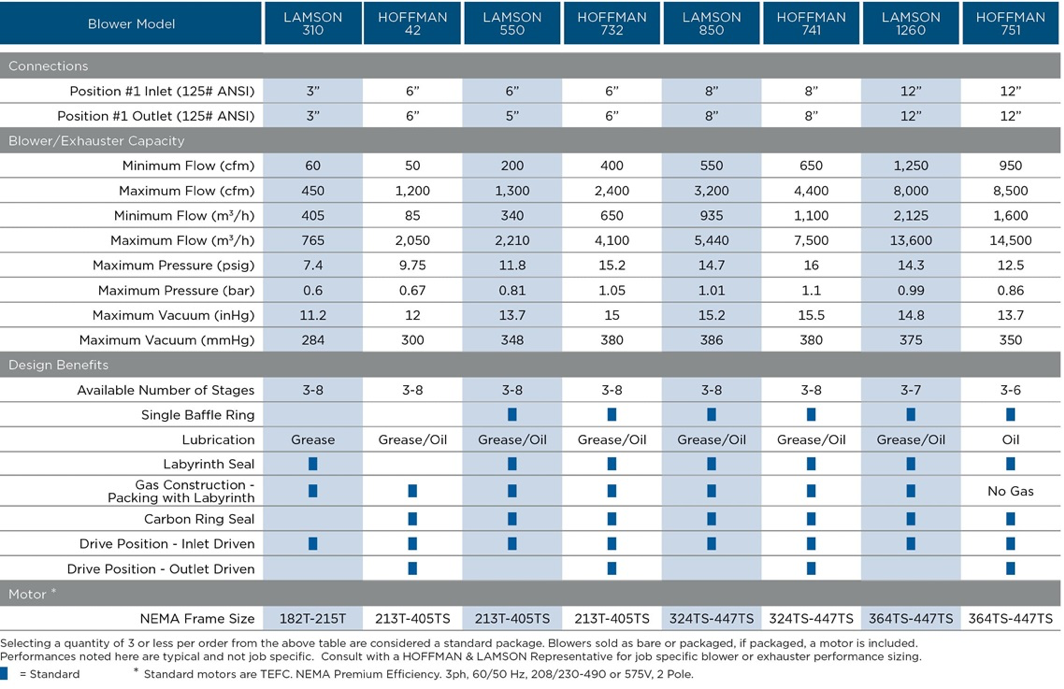

- Hoffman & Lamson’s comprehensive product line of multistage centrifugal blowers are broken into low, medium, and high flow capacity.

- Our models cover a broad performance range with capacities stretching from 80 to 41,000 CFM (130 to 70,000 m3/h) and present their own unique design features and characteristics.

- With models optimized for 60 and 50 Hz markets, we offer efficient performance backed by our unwavering commitment to innovation.